Albeit the battery cell technology advancement and system integration level increase in the past decade, batteries still account for, on average, more than 40% of the total (manufacturing) costs and 25% of the total weight of electric vehicles today. Moreover, for many other mobility sectors, for instance maritime, the technology is still under-developed and cumbersome.

Electric bikes and vehicles can no longer be ignored on the road. Even for freight transport, electrification has become feasible. However, the energy and power requirement is nowhere comparable to that of the transportation industry’s biggest players: shipping. This is mainly due to the cost and weight of the battery. Even smaller boats such as a tug quickly require a capacity comparable to 40 electric cars.

Electric vehicles are typically mass produced, meaning that the fixed costs (design and infrastructure) can be distributed over all vehicles sold. In contrast, boats are not mass produced and thus electric propulsion is expensive customization. Within the SEABAT project, it has been proved that a modular solution can reduce the total costs by up to 50%. In a modular design, all modules are of the same dimensions and can be easily stacked together to meet your power, energy, and space requirements. Opting for a modular battery system provide even an unique vehicle designs that can benefit from economies of scale by using standardized and inexpensive modular components.

Hybrid battery – no more oversizing

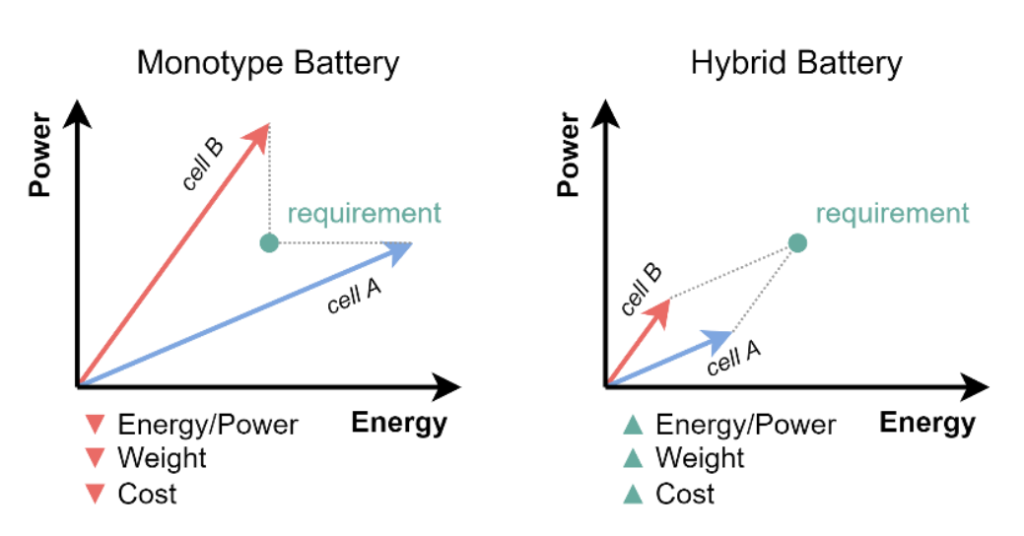

One of the biggest problems in electrification is oversizing the capacity to accommodate both power peaks (e.g., fast charging and maneuvering) and long-term high energy requirements (e.g., to maintain cruising speed). Standard battery systems use only one cell technology. A choice must be made between high energy density (High Energy) batteries that can store large amounts of energy or high power density (High Power) batteries that can quickly release large amounts of energy. The solution to this challenge is a hybrid battery setup, combining High Energy and High Power battery cells. This achieves the optimal balance between performance and volume and will significantly reduce cost and weight.

And how do hybrid batteries work together seamlessly? At Flanders Make, we are experienced in developing the architecture for this hybrid battery setup. In the fall of 2024, the results of this European research project will be presented with a final proof-of-concept. But in the meantime, we have already provided proof that huge profits can be made thanks to this innovative battery storage.

Is modular hybrid battery system a cup of tea for you?

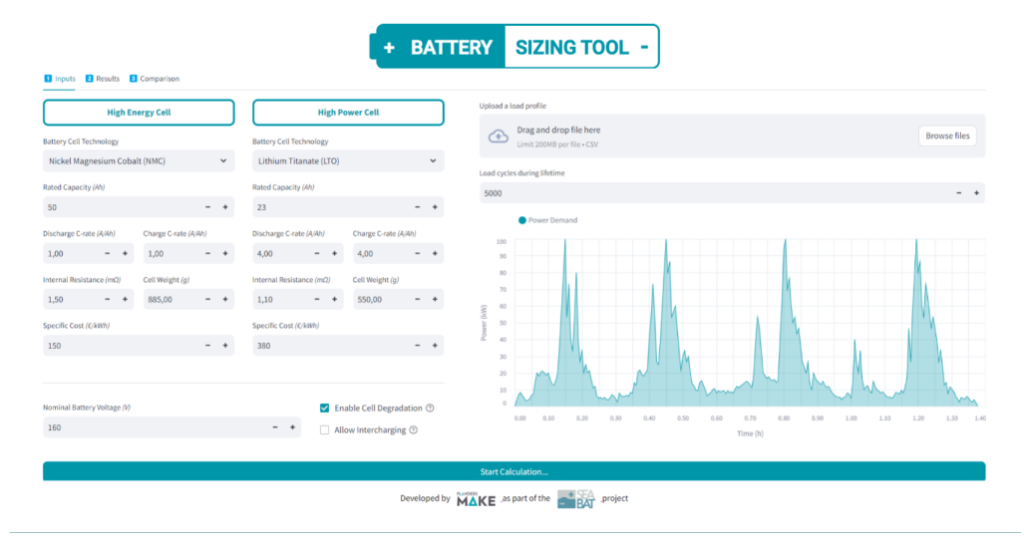

The Flanders Make “battery sizing tool” performs a high-speed and realistic simulation of the optimal battery setup. This immediately tests the advantages of the hybrid concept against a typical monotype system. This customized simulation calculates the battery configuration based on the most relevant parameters of your product: the load profile, the selected cell technology, the expected lifetime, and the desired voltage level. In developing this battery sizing tool, we have received strong support from DAMEN and Fincantieri, who are currently evaluating the electrification potential of their vessel products. Are you a battery professional? It is even better, the battery sizing tool also allows you to impose more constraints. For instance, the optimal charging percentage is taken into account: to optimize battery life, the system will only charge to a maximum of 90% and discharge to 10%. The desired lifetime is also critical. On average, this will be at a life cycle of 10 years, but the aging of different types of battery cells is a complex parameter. The software makes an accurate calculation based on empirical data.

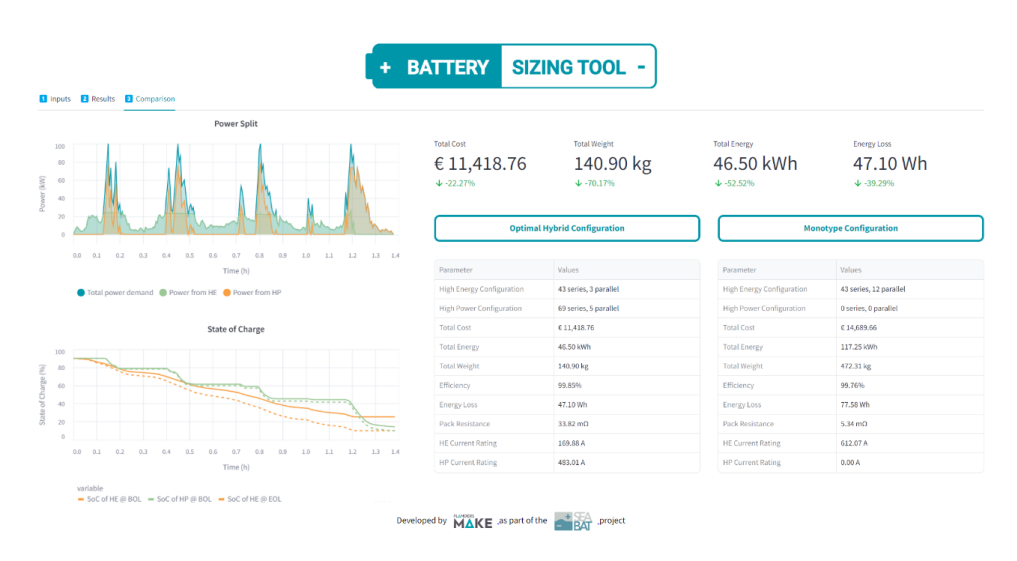

The result of the calculation will show at a glance how the hybrid arrangement is the most optimal for

many applications. This arrangement will ensure that all the energy from the battery pack is used. This

is in contrast to a monotype setup, in which energy remains unused. Both packages are shown side by

side so that the huge gains can be seen. In the example below, the simulation of a small tugboat, the

hybrid solution yields decreases in cost and weight of 20% and more.

This tool is widely applicable: the simulation is not only useful for potential e-ships but also for many other industries, from home batteries to aviation. Moreover, by staying in the forefront of battery energy storage systems research, the battery sizing tool is continuously being maintained and updated (with new features and emerging battery technologies).