Worldwide the transport sector is turning to electrification to reduce emissions and increase efficiency. On the roads we can see that the mass production of electric vehicles is picking up: every passenger car manufacturer now has full-electric options in their portfolio. Similarly, full-electric buses for public transport are available on the market.

Electrification is a key technology to reduce maritime emissions. The International Maritime Organization (IMO) wants to reduce annual greenhouse gas (GHG) emissions from maritime transport by 50% by 2050 compared to 2008, and even pursues efforts towards phasing them out entirely. Electrification is one of the solutions to reach this target, next to other solutions.

However, maritime electric propulsion is not yet mature. For instance, maritime batteries are considerably more expensive than automotive batteries and integrated solutions for ships have not yet started to penetrate the markets.

The reasons that existing large waterborne battery systems are relatively cost-inefficient are:

- A lack of economy of scale. Ships are built in small series and the battery solutions are typically bespoke. This leads to low economies of scale and high assembly costs.

- A lack of dedicated systems. Ships have high-energy missions (e.g. maintaining cruising speed) and high-power peaks (e.g. fast charging, maneuvering). At present a single type of battery is used for both missions. However, a single battery technology cannot cover all the necessary requirements. A common solution is to oversize the capacity by a factor of 2 to as much as 10, which is very costly.

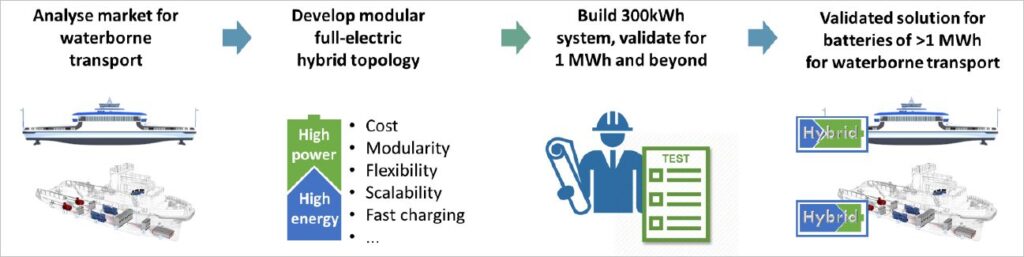

SEABAT takes the challenge head-on to substantially reduce the costs of large waterborne transport battery systems by developing a full-electric maritime hybrid concept that combines high-energy and high-power storage cells.

Read more on the project concept.